每次使用自動焊接設(shè)備焊接操作前的檢查

來源:http://m.tj-moju.com/ 發(fā)布時間:2022-10-18 瀏覽次數(shù):0

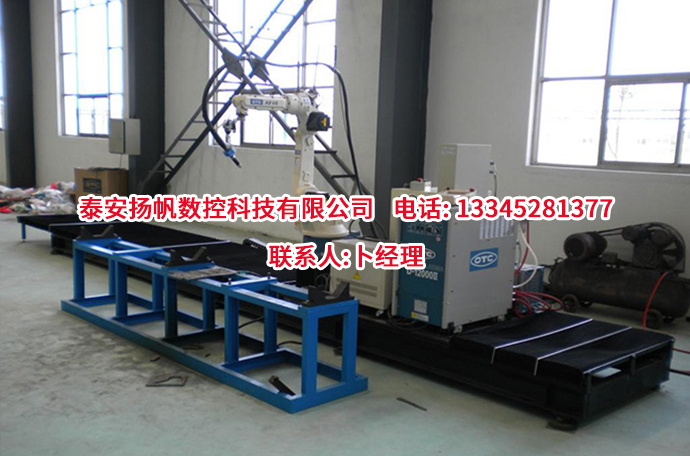

山東自動焊接設(shè)備與其他焊接設(shè)備相比具有更高的自動化程度,其所有部件均選自高質(zhì)量的原始設(shè)備,并且操作非常簡單方便。那么操作員每次使用自動焊接設(shè)備焊接操作前的檢查包含什么內(nèi)容呢?

Compared with other welding equipment, Shandong automatic welding equipment has a higher degree of automation. All its components are selected from high-quality original equipment, and the operation is very simple and convenient. What does the operator check before each welding operation with automatic welding equipment include?

自動焊接設(shè)備檢查:操作員在每次焊接操作前要檢查以下項目:

Safety inspection of automatic welding equipment: the operator shall check the following items before each welding operation:

1.確保焊接機相互良好的接地是可靠的安裝。

1. Ensure that the welding machine is reliably grounded.

2.確保焊接機的輸入和輸出電纜完好無損。

2. Ensure that the input and output cables of the welding machine are intact.

3.安裝并固定了焊接機后,人員要定期對其進行檢查。

3. After the welding machine is installed and fixed, the personnel shall inspect it regularly.

4.不會有內(nèi)部間隙等異常情況。檢查并確認(rèn)送絲輥的凹槽和齒型完好無損,并且在磨損或接觸不良時應(yīng)更換輥和接觸頭塊。

4. There will be no abnormal conditions such as internal clearance. Check and confirm that the groove and tooth profile of the wire feeding roller are intact, and replace the roller and contact head block in case of wear or poor contact.

使用自動焊接設(shè)備的注意事項:

Precautions for using automatic welding equipment:

1.焊槍電纜不要壓得太緊,彎曲角度也不能太小。送絲軟管的半徑不應(yīng)小于150mm,否則內(nèi)部電纜會損壞,可能導(dǎo)致事故。焊接期間請勿更改電壓調(diào)試開關(guān)。

1. The welding gun cable shall not be pressed too tightly and the bending angle shall not be too small. The radius of wire feeding hose shall not be less than 150mm, otherwise the internal cable will be damaged, which may lead to accidents. Do not change the voltage commissioning switch during welding.

2.在焊接操作過程中,請勿觸摸帶電部件,例如焊接機的輸出接口。

2. During the welding operation, do not touch the live parts, such as the output interface of the welding machine.

3.更改或調(diào)試面板旋鈕時,請勿過分用力。自動不銹鋼管焊接機可能會損壞設(shè)備。

3. Do not use excessive force when changing or debugging the panel knob. Automatic stainless steel pipe welding machine may damage the equipment.

4.每次焊接之前,請檢查焊接機的連接是否正確以及接地線是否可靠。

4. Before each welding, please check whether the welding machine is connected correctly and whether the grounding wire is reliable.

相信大家閱讀完文章之后對這一問題有了新的了解和認(rèn)識,如果您想了解更多知識,歡迎多多關(guān)注我們的網(wǎng)站http://m.tj-moju.com動態(tài)。

I believe you will have a new understanding of this issue after reading the article. If you want to know more, please pay more attention to our website http://m.tj-moju.com Dynamic.