自動(dòng)焊接設(shè)備可以焊接哪些工件

來源:http://m.tj-moju.com/ 發(fā)布時(shí)間:2022-12-01 瀏覽次數(shù):0

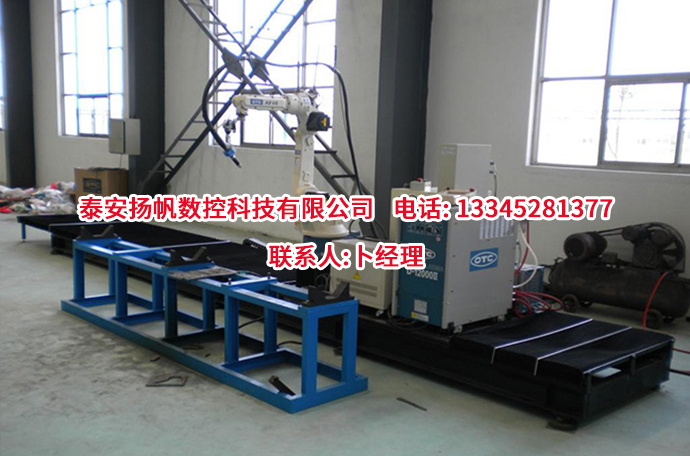

自動(dòng)焊接設(shè)備進(jìn)行焊接的時(shí)候,可以焊接哪些部件,作為壓力容器自動(dòng)焊接設(shè)備廠家,讓山東自動(dòng)焊接設(shè)備廠家?guī)Т蠹夜餐私庖幌伦詣?dòng)焊接設(shè)備可以焊接哪些工件!

When the automatic welding equipment is used for welding, which parts can be welded? As the manufacturer of automatic welding equipment for pressure vessels, let the Shandong automatic welding equipment manufacturer take you to know what workpieces can be welded by the automatic welding equipment!

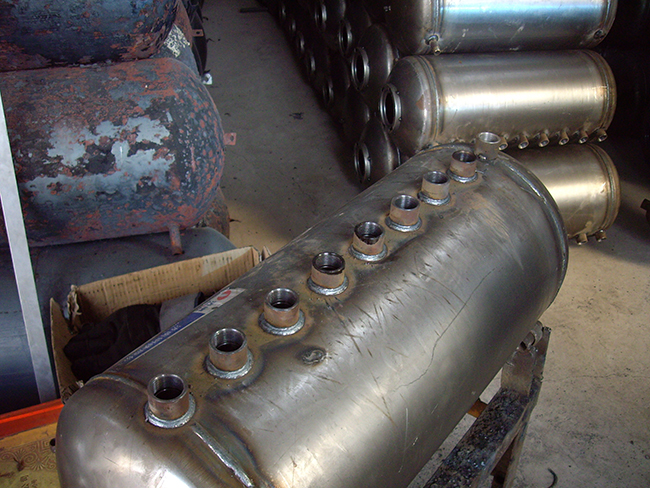

1、法蘭管件。法蘭管件屬于環(huán)縫工件,在使用中對連接處的焊接質(zhì)量要求較高,傳統(tǒng)焊接中對異徑管以及環(huán)縫焊接存在的工藝?yán)щy,容易收到環(huán)境因素的影響出現(xiàn)焊接缺陷,自動(dòng)焊接設(shè)備能夠根據(jù)路徑設(shè)置實(shí)現(xiàn)示教焊接工作,能夠根據(jù)不同法蘭管件的焊縫進(jìn)行填充,冷卻后的焊縫美觀且牢固。

1. Flanged pipe fittings. Flange pipe fittings belong to circumferential seam workpieces, and the welding quality of the joints is required to be high in use. The process difficulties of reducing pipes and circumferential seam welding in traditional welding are easy to be affected by environmental factors, and welding defects occur. The automatic welding equipment can implement teaching welding according to the path settings, and can fill according to the welds of different flange pipe fittings. The cooled welds are beautiful and firm.

2、箱體結(jié)構(gòu)。隨著我國運(yùn)輸行業(yè)的發(fā)展,對箱體運(yùn)輸?shù)男枨罅坎粩嗵岣?,箱體結(jié)構(gòu)也廣泛應(yīng)用于工業(yè)制造以及生活起居中,傳統(tǒng)焊接無法滿足焊接需求,自動(dòng)焊接設(shè)備搭配焊接輔機(jī)減輕工人的勞動(dòng)強(qiáng)度,在焊接過程中,實(shí)現(xiàn)二十四小時(shí)不間斷生產(chǎn),提高焊接效率,具備智能焊接系統(tǒng),根據(jù)焊縫規(guī)格下放焊接材料。

2. Box structure. With the development of the transportation industry in China, the demand for box transportation is increasing. The box structure is also widely used in industrial manufacturing and daily life. Traditional welding cannot meet the demand for welding. Automatic welding equipment with welding auxiliaries reduces the labor intensity of workers. In the welding process, 24-hour continuous production is achieved to improve the welding efficiency. With intelligent welding system, welding materials are distributed according to the weld specifications.

3、不銹鋼板。根據(jù)不銹鋼板厚不同,需要用到的焊接參數(shù)也是不同的,傳統(tǒng)焊接對于鋼板的厚度無法把控,容易出現(xiàn)焊穿、焊點(diǎn)飛濺等缺陷,出現(xiàn)焊接缺陷導(dǎo)致成本增加,自動(dòng)焊接設(shè)備實(shí)現(xiàn)智能化焊接,柔性焊接系統(tǒng)可以根據(jù)不同板厚的不銹鋼工件靈活應(yīng)變,穩(wěn)定質(zhì)量。

3. Stainless steel plate. According to the different thickness of stainless steel plates, the required welding parameters are also different. Traditional welding can not control the thickness of steel plates, and is prone to defects such as weld penetration and weld spatter. The cost increases due to welding defects. The automatic welding equipment realizes intelligent welding. The flexible welding system can flexibly strain and stabilize the quality according to the stainless steel workpieces with different thickness.

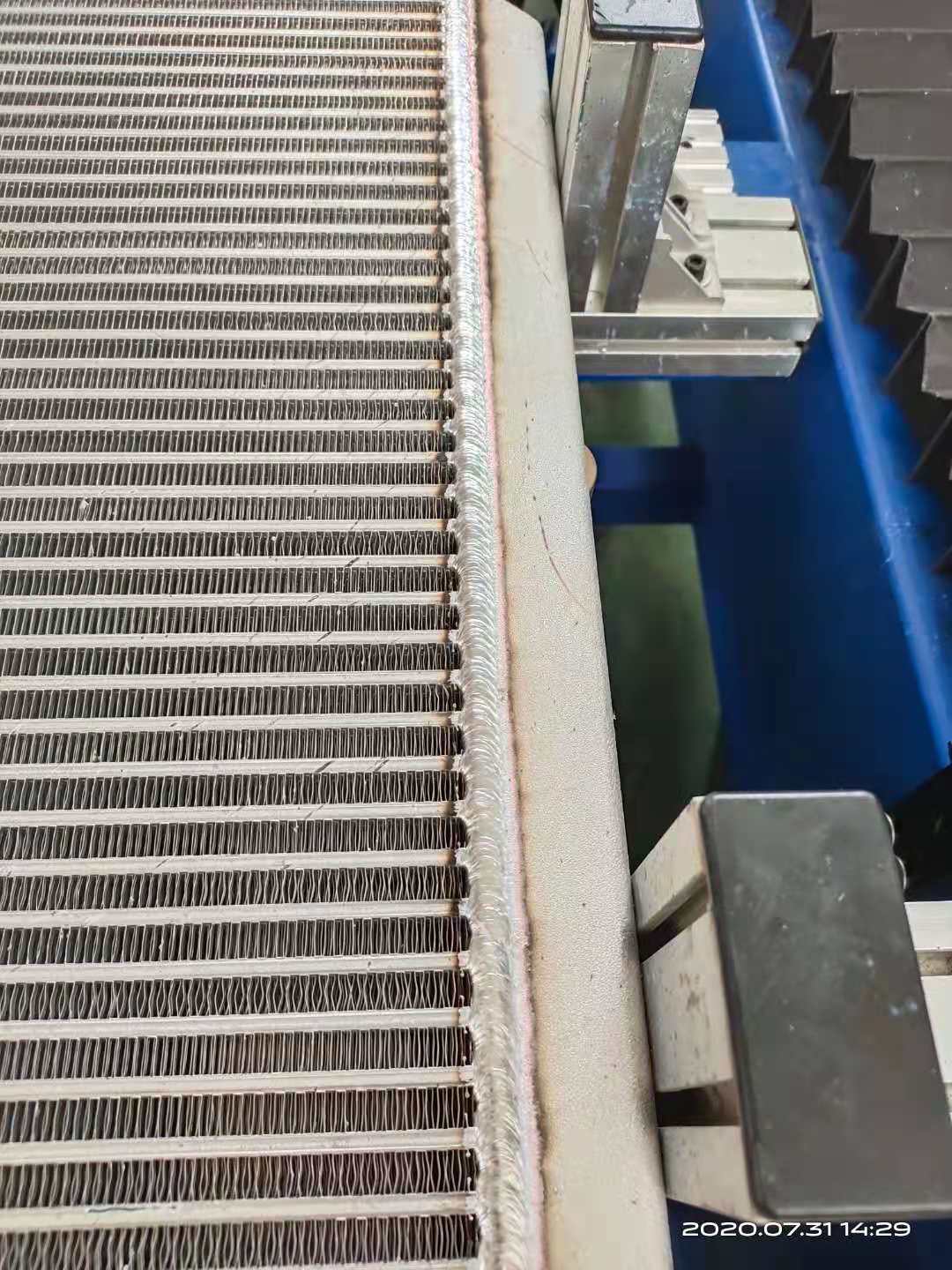

4、鋁合金工件。鋁合金材質(zhì)的熔點(diǎn)較低,傳統(tǒng)焊接中,很難保證焊接質(zhì)量的穩(wěn)定,容易造成鋁合金材質(zhì)的變形,自動(dòng)焊接設(shè)備可以根據(jù)材質(zhì)需求進(jìn)行焊接,使用工裝夾具進(jìn)行夾緊,減少工件的變形。

4. Aluminum alloy workpiece. The melting point of aluminum alloy material is low. In traditional welding, it is difficult to ensure the stability of welding quality, which is easy to cause deformation of aluminum alloy material. The automatic welding equipment can weld according to the material requirements, and clamp with tooling fixtures to reduce the deformation of the workpiece.

自動(dòng)焊接設(shè)備可以焊接哪些工件?我們從四個(gè)方面來講解了問題,您對此有什么發(fā)現(xiàn)嗎?更多相關(guān)信息就來我們網(wǎng)站http://m.tj-moju.com了解。

What workpieces can automatic welding equipment weld? We explained the problem from four aspects. What do you find? Come to our website for more information http://m.tj-moju.com Understand.

上一篇:焊接專機(jī)設(shè)備操作規(guī)范參考信息

下一篇:使用焊接專機(jī)前的基本設(shè)備了解