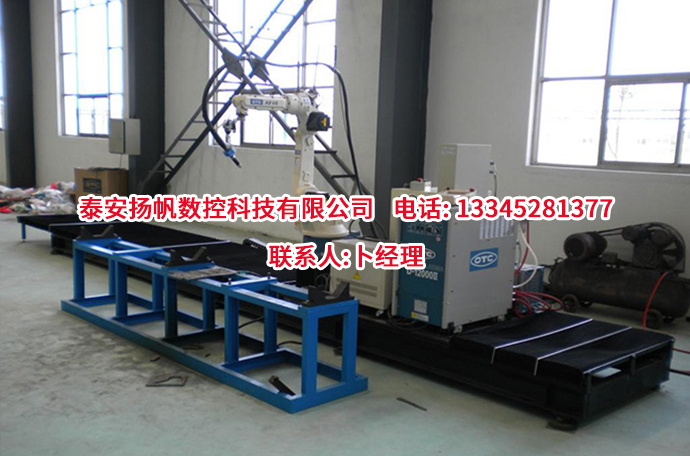

環(huán)縫自動(dòng)焊接專機(jī)的功能特點(diǎn)簡(jiǎn)介

來(lái)源:http://m.tj-moju.com/ 發(fā)布時(shí)間:2022-11-10 瀏覽次數(shù):0

環(huán)縫是指形成環(huán)形,平行于地面,由焊工正常站立或蹲著焊接的環(huán)焊縫。所以這種焊接方法叫環(huán)焊,這種焊機(jī)叫環(huán)焊機(jī)。下面山東焊接專機(jī)廠家就來(lái)講講環(huán)縫自動(dòng)焊接專機(jī)的功能特點(diǎn)。

Circumferential weld refers to the circumferential weld that is formed in a circle and parallel to the ground, and is welded by the welder standing or squatting normally. So this welding method is called girth welding, and this welding machine is called girth welding machine. Next, the Shandong welding machine manufacturer will talk about the functional characteristics of the automatic circumferential welding machine.

焊接對(duì)象

Welding objects

油缸:工件長(zhǎng)度:≤2000mm、工件直徑:90-300mm、工件焊前狀態(tài):裝配

Oil cylinder: workpiece length: ≤ 2000mm, workpiece diameter: 90-300mm, workpiece status before welding: assembly

功能簡(jiǎn)介及特點(diǎn)

Function introduction and characteristics

調(diào)整,速度大,效率高,上下料方便快捷??刂葡到y(tǒng)靈敏可靠、故障少,且操作和維護(hù)方便。工件旋轉(zhuǎn),采用變頻器單元驅(qū)動(dòng),工件旋轉(zhuǎn)支撐采用梯型螺紋上下,根據(jù)工件直徑調(diào)解中心高度,和壓緊環(huán)配合來(lái)固定和壓緊工件并且由尾座頂緊工件中心,確保工件的外形尺寸與焊接的配合。頂?shù)募饪筛鶕?jù)不同工件更換。

Adjustment, high speed, high efficiency, convenient loading and unloading. The control system is sensitive and reliable, with few failures and convenient operation and maintenance. The workpiece rotation is driven by the frequency converter unit. The workpiece rotation support adopts the ladder thread up and down. The center height is adjusted according to the workpiece diameter, and the workpiece is fixed and compressed by matching with the clamping ring. The tailstock is used to top the workpiece center to ensure that the overall dimensions of the workpiece are compatible with the welding. The tip of the top can be changed according to different workpieces.

床身裝有旋轉(zhuǎn)汽缸,能使工件旋轉(zhuǎn)30度或45度的夾角,從而使油缸內(nèi)環(huán)焊縫和油缸端面平環(huán)焊縫保證穩(wěn)定的焊接質(zhì)量及美觀的焊縫成型焊接機(jī)構(gòu)采用電機(jī)帶動(dòng)齒輪齒條來(lái)實(shí)現(xiàn)直線運(yùn)動(dòng),相比單采用圓形滑線導(dǎo)軌運(yùn)動(dòng),焊槍定位更為準(zhǔn)確。

The machine bed is equipped with a rotary cylinder, which can rotate the workpiece at an included angle of 30 or 45 degrees, so that the circumferential weld in the cylinder and the flat circumferential weld on the end face of the cylinder can ensure stable welding quality and beautiful weld formation. The welding mechanism uses the motor to drive the gear rack to achieve linear movement. Compared with the circular sliding guide rail movement, the welding gun positioning is more accurate.

注意事項(xiàng):

Safety precautions:

操作人員應(yīng)按規(guī)定穿戴工作服、工作鞋、護(hù)目鏡、口罩等勞動(dòng)保護(hù)用品。每次啟動(dòng)推車并抬起橫擔(dān)時(shí),都需要確認(rèn)運(yùn)行區(qū)域內(nèi)沒(méi)有人或異物,才能啟動(dòng)推車或橫擔(dān)。禁止在橫擔(dān)、機(jī)頭、工作平臺(tái)等設(shè)備上存放工具和殘余雜物。須妥善管理焊槍調(diào)整專用工具,防止墜落傷害。

Operators shall wear work clothes, work shoes, goggles, masks and other labor protection articles as required. Every time the trolley is started and the cross arm is lifted, it is necessary to confirm that there is no person or foreign matter in the operation area before starting the trolley or cross arm. It is prohibited to store tools and residues on cross arms, handpieces, working platforms and other equipment. Special tools for welding gun adjustment must be properly managed to prevent falling injury.

卸載鋼瓶時(shí),移開(kāi)手推車以免損壞機(jī)器。焊接時(shí)應(yīng)注意弧光對(duì)眼睛和皮膚的灼傷,特別提醒外人。嚴(yán)禁站在橫擔(dān)下。

When unloading cylinders, remove the trolley to avoid damaging the machine. During welding, attention shall be paid to burns to eyes and skin caused by arc light, and outsiders shall be specially reminded. It is strictly forbidden to stand under the cross arm.

環(huán)縫自動(dòng)焊接專機(jī)的速度快,效率高,提高了工作效率。以上就是環(huán)縫焊接專機(jī)功能及特點(diǎn)介紹相關(guān)信息,您有任何問(wèn)題就來(lái)我們網(wǎng)站http://m.tj-moju.com進(jìn)行咨詢了解吧!

The special automatic girth welding machine is fast and efficient, which improves the working efficiency. The above information is about the functions and features of the special girth welding machine. If you have any questions, please come to our website http://m.tj-moju.com Consult and understand!

上一篇:企業(yè)在操作自動(dòng)焊接設(shè)備時(shí)要注意什么

下一篇:焊接變位機(jī)其中的卡盤的保養(yǎng)方法