操作焊接專機時應注意的一些事項

來源:http://m.tj-moju.com/ 發(fā)布時間:2023-03-04 瀏覽次數(shù):0

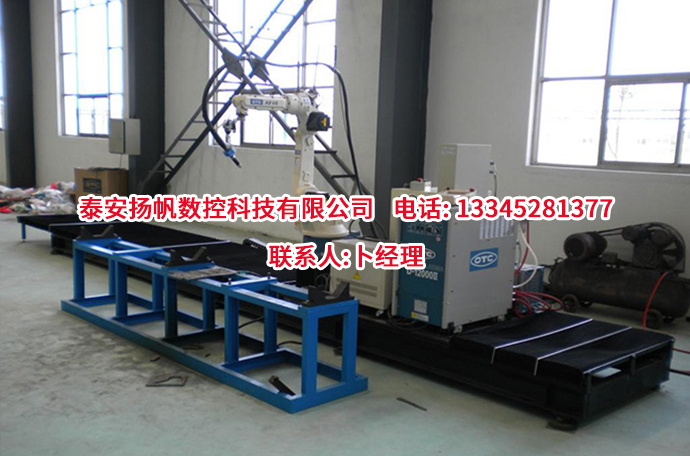

如今市場對焊接專機的需求也在不斷增大,但如果在使用過程中操作不當,勢必將會給生產(chǎn)企業(yè)帶來很多的不必要的人體傷害或者是經(jīng)濟損失,下面給您簡述一下操作山東焊接專機時應注意的一些事項。

Nowadays, the market demand for special welding machines is also increasing. However, if the machine is operated improperly in the process of use, it will inevitably bring a lot of unnecessary human injuries or economic losses to the production enterprises. Here is a brief description of some matters that should be paid attention to when operating Shandong special welding machines.

(1)焊接專機操作人員應該嚴格做好防護措施,穿戴好防護衣物,工作場內(nèi)不宜堆放易燃、易爆等物品,以防止發(fā)生火災或者觸電等事故;

(1) Operators of special welding machines should take strict safety protection measures, wear protective clothing, and should not stack flammable and explosive articles in the workplace to prevent fire or electric shock accidents;

(2)焊接專機適合在室內(nèi)操作,并配備好可靠的地線且電焊機導線長度不宜過長;

(2) The special welding machine is suitable for indoor operation, and is equipped with reliable ground wire, and the length of the welding wire should not be too long;

(3)當需要多臺焊接專機并列安裝時,要保證各臺專機之間的距離達3米,并且必須接在不同的刀線上有獨立的開關(guān)控制;

(3) When multiple special welding machines are required to be installed in parallel, the safety distance between each special machine should be guaranteed to be 3 meters, and independent switch control must be connected to different cutter lines;

(4)在焊接專機開始使用前,應該對整臺焊接專機做充分的檢查,確保氣壓、液壓系統(tǒng)無泄漏沒有任何故障時才能使用;

(4) Before the use of the special welding machine, the whole special welding machine should be fully checked to ensure that the air pressure and hydraulic system are free of leakage and any fault before use;

(5)焊接專機的電路應長期做檢查,以保證機器的正常動作;

(5) The circuit of the special welding machine should be checked for a long time to ensure the normal operation of the machine;

(6)焊接專機周圍要避免雜物,防止電源或電線受損發(fā)生意外。在通電情況下不可以自行打開數(shù)控控制箱及各種線路,防止觸電。

(6) Avoid sundries around the special welding machine to prevent accidents caused by damage to the power supply or wires. It is not allowed to open the NC control box and various lines by itself when the power is on to prevent electric shock.

(7)離開崗位前和下班前要關(guān)閉電源和氣源,防止他人隨意操作。遇到焊接問題,及時上報領導聯(lián)系廠家,做出方案才可調(diào)整。

(7) Turn off the power supply and gas source before leaving the post and after work to prevent others from operating at will. In case of welding problems, timely report to the leader to contact the manufacturer and make a plan before adjustment.

操作焊接專機時應注意的一些事項相關(guān)內(nèi)容就講解到這里了,您對此有怎樣的疑難問題或者需求就來我們網(wǎng)站http://m.tj-moju.com咨詢吧!

This is how to explain some matters needing attention when operating the special welding machine. Please come to our website if you have any questions or needs http://m.tj-moju.com Ask!