臥式環(huán)縫焊接機(jī)用于筒體和蓋板環(huán)縫對(duì)接焊接

來(lái)源:http://m.tj-moju.com/ 發(fā)布時(shí)間:2022-06-28 瀏覽次數(shù):0

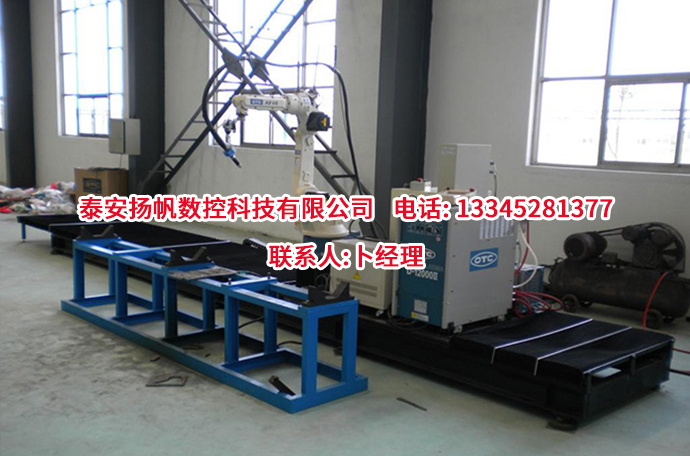

臥式雙環(huán)縫焊接專機(jī)用于缸體與蓋板環(huán)縫的對(duì)焊。該系統(tǒng)主要包括機(jī)械部分、焊接電源弧長(zhǎng)偏航控制系統(tǒng)、焊接輔助設(shè)備。主要功能包括焊接啟動(dòng)、停止、焊接時(shí)間控制、焊接電流控制、旋轉(zhuǎn)位置控制、焊接速度控制、預(yù)留自動(dòng)送絲功能等。

Horizontal double circumferential seam welding machine is used for butt welding of circumferential seam between cylinder block and cover plate. The system mainly includes mechanical part, arc length yaw control system of welding power supply and welding auxiliary equipment. The main functions include welding start, stop, welding time control, welding current control, rotation position control, welding speed control, reserved automatic wire feeding function, etc.

可編程控制器配置為實(shí)現(xiàn)控制系統(tǒng)的邏輯控制,具有小型化、高速、高性能、大容量等特點(diǎn)。控制系統(tǒng)的其他電氣元件,如繼電器、接觸器、存儲(chǔ)單元、信號(hào)采用和傳輸元件,各種行程開關(guān)均采用元件,使控制系統(tǒng)的可靠性大大提高??刂葡到y(tǒng)與焊接電源集成,可實(shí)現(xiàn)設(shè)備動(dòng)作與焊接過(guò)程的無(wú)縫銜接,達(dá)到理想的焊接質(zhì)量。

The programmable controller is configured to realize the logic control of the control system and has the characteristics of miniaturization, high speed, high performance and large capacity. Other electrical components of the control system, such as relays, contactors, storage units, signal adoption and transmission components, and various travel switches adopt high-quality components, which greatly improves the reliability of the control system. The control system is integrated with the welding power supply, which can realize the seamless connection between the equipment action and the welding process, and achieve the ideal welding quality.

采用臥式焊臺(tái)結(jié)構(gòu)和導(dǎo)軌床身,可靠保證氣動(dòng)尾座與機(jī)頭距離可調(diào)。機(jī)頭轉(zhuǎn)動(dòng),主軸由變頻電機(jī)驅(qū)動(dòng),焊槍支架由減速電機(jī)無(wú)級(jí)調(diào)速驅(qū)動(dòng)。該產(chǎn)品由轉(zhuǎn)臺(tái)、氣動(dòng)夾緊、焊槍氣動(dòng)升降機(jī)構(gòu)等組成,裝卸方便,機(jī)動(dòng)性好。電控系統(tǒng)采用程序控制,焊接參數(shù)預(yù)置,操作簡(jiǎn)單,設(shè)置方便,自動(dòng)化程度高。也可以根據(jù)需要使用PLC編程控制器的控制單元,通過(guò)修改控制軟件程序和焊接參數(shù)來(lái)調(diào)整設(shè)備的功能。

The horizontal welding table structure and guide rail bed are adopted to reliably ensure that the distance between the Pneumatic Tailstock and the machine head is adjustable. The machine head rotates, the main shaft is driven by the frequency conversion motor, and the welding gun bracket is driven by the stepless speed regulation of the reduction motor. The product is composed of rotary table, pneumatic clamping, welding gun pneumatic lifting mechanism, etc., with convenient loading and unloading and good mobility. The electric control system adopts program control, welding parameter presetting, simple operation, convenient setting and high degree of automation. The control unit of PLC programmable controller can also be used as required to adjust the functions of the equipment by modifying the control software program and welding parameters.

山東自動(dòng)焊接設(shè)備廠家認(rèn)為,鎢極氣體保護(hù)焊是一種非熔化氣體保護(hù)焊,利用鎢極與工件之間的電弧使金屬熔化形成焊縫。在焊接過(guò)程中,鎢電極不會(huì)熔化,僅起到真正電極的作用。

Shandong automatic welding equipment manufacturers believe that tungsten gas shielded welding is a kind of non melting gas shielded welding, which uses the arc between tungsten electrode and workpiece to melt the metal to form a weld. In the welding process, the tungsten electrode will not melt, but only acts as a real electrode.

同時(shí),從焊槍中送出氬氣作為保護(hù)氣體。鎢電極可以控制熱量輸入。是鈑金連續(xù)焊接和底焊的一種方法。焊接電流是脈沖的形式,所以學(xué)會(huì)了焊接管道。這種方法幾乎可以用于所有金屬的焊接,尤其適用于鋁金屬的焊接。采用這種焊接方法,焊縫質(zhì)量高,焊接速度快。

At the same time, argon is sent out from the welding gun as the shielding gas. Tungsten electrode can control heat input. It is a method of continuous welding and bottom welding of sheet metal. Welding current is in the form of pulse, so I learned to weld pipes. This method can be used to weld almost all metals, especially aluminum. With this welding method, the weld quality is high and the welding speed is fast.

以上就是問(wèn)題解答的相關(guān)內(nèi)容了,希望能夠幫助到大家,如對(duì)這一問(wèn)題還存在任何疑問(wèn),都?xì)g迎關(guān)注我們網(wǎng)站http://m.tj-moju.com并咨詢我們的工作人員,將竭誠(chéng)為您服務(wù)。

The above is the relevant content of the question answer. I hope it can help you. If you still have any questions about this problem, you are welcome to follow our website http://m.tj-moju.com And consult our staff, will serve you wholeheartedly.

上一篇:焊接專機(jī)從分類使用事項(xiàng)了解起來(lái)

下一篇:自動(dòng)焊接專機(jī)分類和注意事項(xiàng)